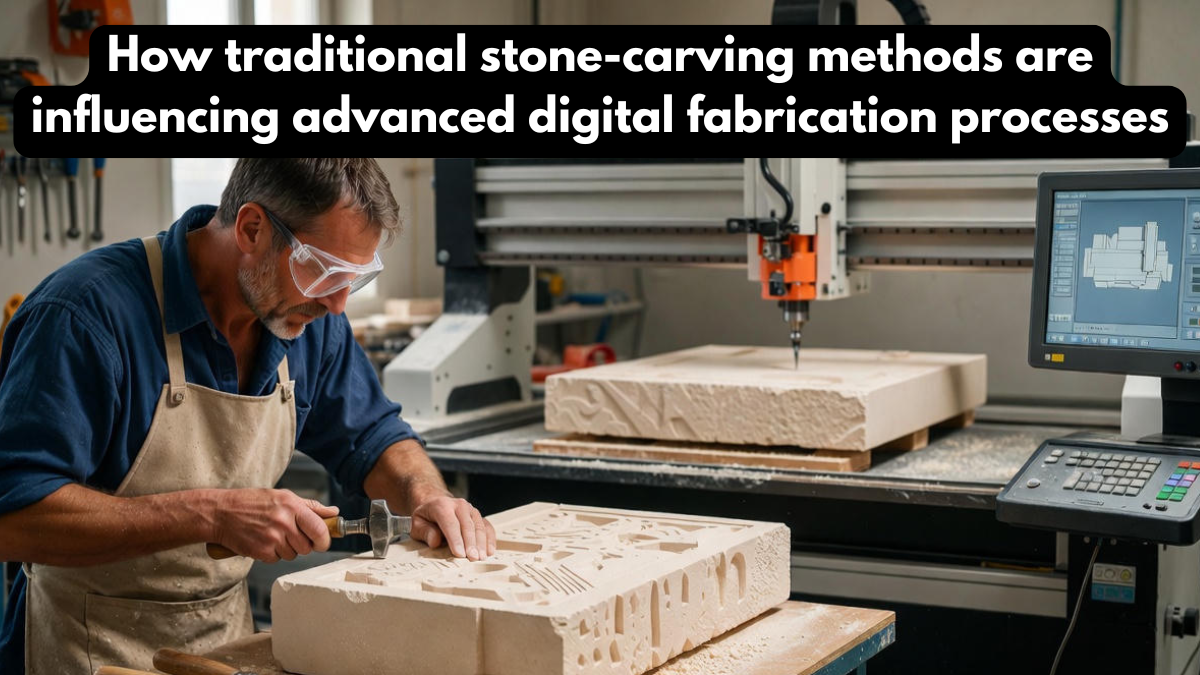

Although technology continues to reshape the architectural and design industries, traditional stone-carving techniques remain a profound source of inspiration for modern digital fabrication processes. The precision, craftsmanship, and tactile understanding gained from centuries of stone carving have laid the groundwork for today’s automated and algorithm-driven manufacturing systems. As architects and engineers explore new ways to merge artistry with technological efficiency, ancient carving methods are reentering the spotlight, influencing how digital tools interpret texture, weight, form, and structural integrity.

The Timeless Foundation of Stone-Carving Craft

For thousands of years, artisans relied on chisels, hammers, and meticulous hand skills to shape natural stone into lasting architectural and artistic creations. These stone-carving techniques formed the basis of structural design, aesthetic composition, and material understanding. Skilled carvers learned how stone behaves under pressure, how to create smooth transitions, and how to maintain stability in intricate designs. This experiential knowledge, grounded in the tangible world, has become a valuable reference point for today’s digital fabrication innovators, who aim to replicate or enhance the precision once achieved through manual craftsmanship.

How Ancient Skills Influence Modern Technologies

As computational design grows, designers increasingly integrate lessons from stone-carving techniques into digital workflows. Concepts like incremental removal, layered geometry, and stress distribution are now incorporated into algorithmic models. These parallels allow digital fabrication machines—such as CNC routers, water-jet cutters, and robotic arms—to mimic the thoughtful pacing and sensitivity once embodied by human carvers. The result is a hybrid design language that respects tradition while embracing cutting-edge production methods capable of creating both simple forms and complex, biomimetic structures.

Material Understanding and Design Accuracy

Traditional stone-carving techniques highlight the importance of listening to materials, a philosophy that deeply influences digital fabrication today. Stone, like many natural materials, varies in density, grain, and fracture tendencies. Ancient artisans studied these variations to prevent tool damage and ensure structural consistency. In modern fabrication labs, engineers use similar principles by programming machines to analyze material composition before cutting. High-resolution scanning and adaptive tool-path algorithms allow machines to respond dynamically to material differences, ensuring accuracy while protecting equipment. This blending of ancient instinct and modern analytics reflects a powerful evolution in material-based design.

Comparison Table: Traditional Stone Carving vs. Digital Fabrication

The table below outlines how traditional stone-carving techniques align with modern digital fabrication methods:

| Aspect | Traditional Stone Carving | Digital Fabrication |

|---|---|---|

| Skill Source | Manual craftsmanship | Computer algorithms and robotics |

| Material Interaction | Tactile, intuitive | Data-driven and automated |

| Precision Level | High but human-dependent | Extremely high with minimal error |

| Design Flexibility | Limited by hand tools | Unlimited with parametric modeling |

| Production Speed | Slow and labor-intensive | Fast and scalable |

This comparison shows how historical practices continue to inform modern fabrication strategies, ensuring that cultural and aesthetic values persist in technologically advanced design.

Expanding the Future of Architecture and Design

Integrating stone-carving techniques into digital fabrication systems opens new creative possibilities. Architects can recreate ancient aesthetic styles with contemporary precision or develop futuristic structures inspired by natural material behaviors. The resurgence of tactile craftsmanship within digital frameworks encourages designers to think beyond pure efficiency and embrace emotional and cultural connections to materials. As technology continues advancing, the fusion of traditional skills with digital tools will form a new architectural identity that is both innovative and rooted in heritage.

Conclusion

The influence of traditional stone-carving techniques on modern digital fabrication processes highlights the enduring value of ancient knowledge in shaping future technologies. By combining the tactile wisdom of craftsmanship with the precision of automated systems, designers can create structures that reflect both historical artistry and cutting-edge innovation. This evolving relationship ensures that the human touch remains present even as fabrication becomes increasingly digitalized.

FAQs

How do stone-carving techniques influence digital fabrication?

They provide foundational principles of material behavior, precision, and structural understanding that guide modern automated workflows.

Why are traditional carving skills still relevant today?

Their emphasis on craftsmanship and material awareness enriches digital fabrication by promoting accuracy and thoughtful design.

Can digital tools replicate the effects of hand carving?

Yes, many machines use algorithms inspired by stone-carving techniques to mimic the depth, texture, and rhythm of manual craftsmanship.

What advantages come from blending old and new fabrication methods?

The combination enhances creativity, improves material efficiency, and preserves cultural artistry within modern digital fabrication projects.

Click here to learn more